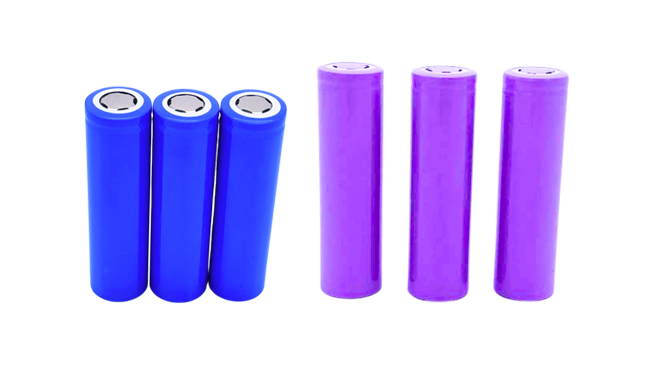

18650 lithium batteries, with their excellent performance and long history of use, are still widely present in our lives today. This type of battery plays an indispensable role in many fields, with obvious advantages and relatively high safety, and is even widely used in large equipment.

18650 lithium batteries are generally divided into two types: energy type and rate type. Energy type batteries are mainly characterized by large capacity, but the discharge current is relatively small;

18650 lithium batteries, with their mature technology and high cost-effectiveness, are widely used in the following fields:

The production of 18650 lithium batteries involves multiple precision processes, including cell manufacturing, PACK assembly, and testing. Battsys Battery's production line integrates automation and intelligence technologies, and the specific process is as follows:

The concept of battery is used very frequently, and with a little attention, we will find that there are actually three differences in using this concept: broad, narrow, and narrow.

The application of lithium battery packs and precautions for their use. Lithium batteries are a representative work of new energy in the 21st century, and they are also a new milestone in the industrial field.

When a single battery or battery pack is allowed to be charged inside a flameproof enclosure, the battery should be equipped with a protective circuit to prevent overcharging;

The current situation of lithium battery energy storage and the advantages of lithium batteries in the field of energy storage. As lithium batteries enter the stage of large-scale application,

E-Mail: inquiry@fentbattery.com

Tel: 0086 20 3901-1403

Address: No.3, Dongli Road, Xili, Dongyong Town, Nansha District, Guangzhou City, China

Copyright@ China lithium ion battery manufacturers & suppliers & producers | Lithium Battery Factory & Company-BATTSYS Sitemap