The secondary utilization of lithium-ion batteries is still in the transitional stage of rechargeable batteries, usually requiring 3-5 charges before the transitional stage.

Firstly, excessively low battery levels have a negative impact on the lifespan of polymer lithium batteries, with the number of charge and discharge cycles being secondary.

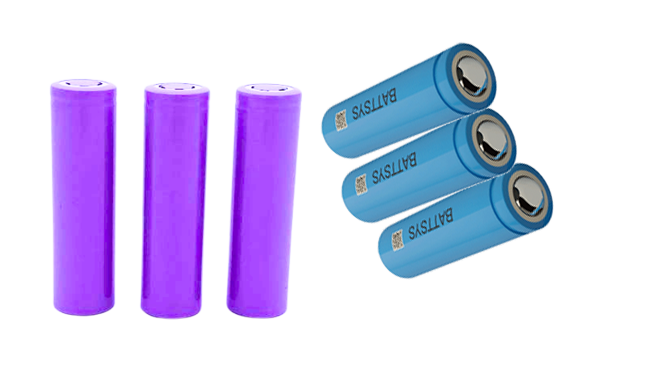

Cylindrical high-temperature lithium batteries can also be divided into many types, such as cylindrical 18650 high-temperature lithium batteries, cylindrical polymer high-temperature lithium batteries, ternary

Different manufacturers have different naming standards, but universal batteries are all based on the same standard, and the specifications and other information of the battery may

Before activating the polymer lithium battery charger to start charging, it will supply a small current to the battery and simultaneously detect changes in battery voltage,

The governance system for energy polymer lithium batteries can effectively monitor, maintain, balance energy, and issue fault alarms for polymer lithium battery packs,

The working principle of high-temperature lithium batteries refers to their charging and discharging principles. When charging the battery, lithium ions are generated on the positive side of the battery,

The principle of high-temperature lithium batteries refers to its basic principles of charging and discharging. When charging a battery,

E-Mail: inquiry@fentbattery.com

Tel: 0086 20 3901-1403

Address: No.3, Dongli Road, Xili, Dongyong Town, Nansha District, Guangzhou City, China

Copyright@ China lithium ion battery manufacturers & suppliers & producers | Lithium Battery Factory & Company-BATTSYS Sitemap