Can multiple 18650 batteries be connected in series to obtain 12V voltage and be used as an emergency starting power source for cars? From the question, it seems that most of the cars we use have a 12V voltage,

Lithium batteries are a type of battery that uses lithium metal or lithium alloy as the positive/negative electrode material and a non-aqueous electrolyte solution. So, have you learned about the main materials of lithium batteries?

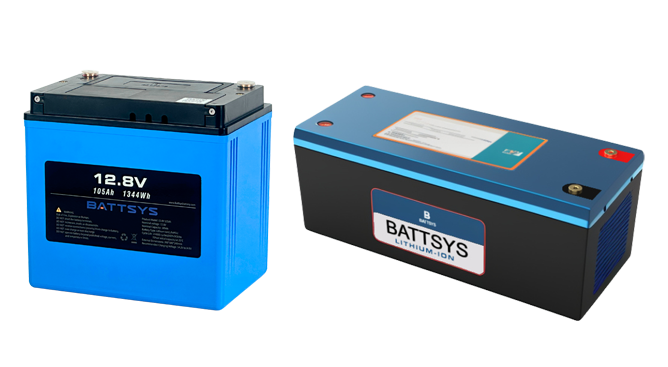

How to choose 18650 lithium batteries? With the increasing market demand, the lithium battery industry is constantly expanding. Various brands of lithium batteries in the market are mixed and difficult to distinguish between good and bad! Next, BATTSYS will give you some tips to take a look together.

Samsung's solid-state battery research and development is handled by Samsung SDI, a subsidiary of Samsung responsible for battery research and production.

When receiving feedback from a customer that the cylindrical 18650 lithium battery pack cannot charge or has no output (for example, the Sanyo 18650, 11.1V lithium battery pack), the battery is now confirmed, tested and analyzed as follows:

Electric vehicles are a green sunrise industry with a history of decades of development in China. As a power source for electric vehicles, lithium batteries are highly favored by consumers due to their lightweight,

Battsys battery has developed 12 safety precautions based on the characteristics of 18650 lithium batteries:

18650 lithium battery production requires protective circuits to prevent the battery from being overcharged or discharged. Of course, this is necessary for lithium batteries,

E-Mail: inquiry@fentbattery.com

Tel: 0086 20 3901-1403

Address: No.3, Dongli Road, Xili, Dongyong Town, Nansha District, Guangzhou City, China

Copyright@ China lithium ion battery manufacturers & suppliers & producers | Lithium Battery Factory & Company-BATTSYS Sitemap