Which is better,

lithium battery soft pack or lithium battery hard pack?

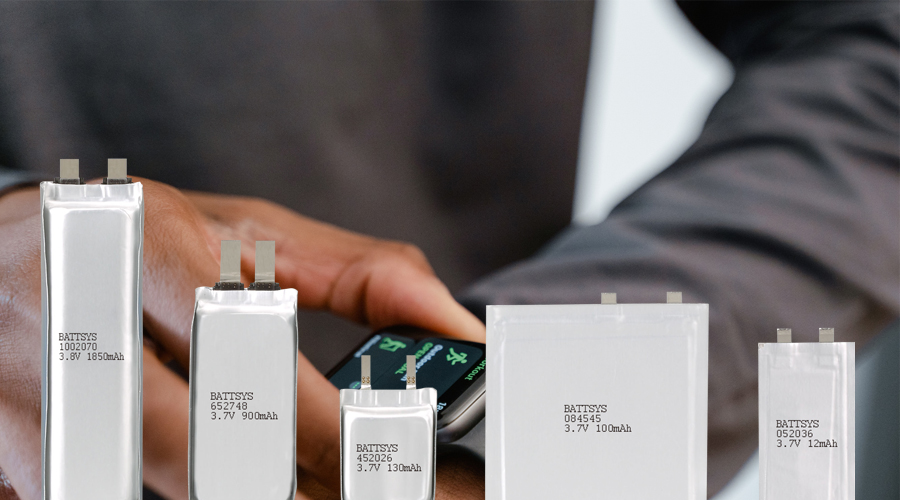

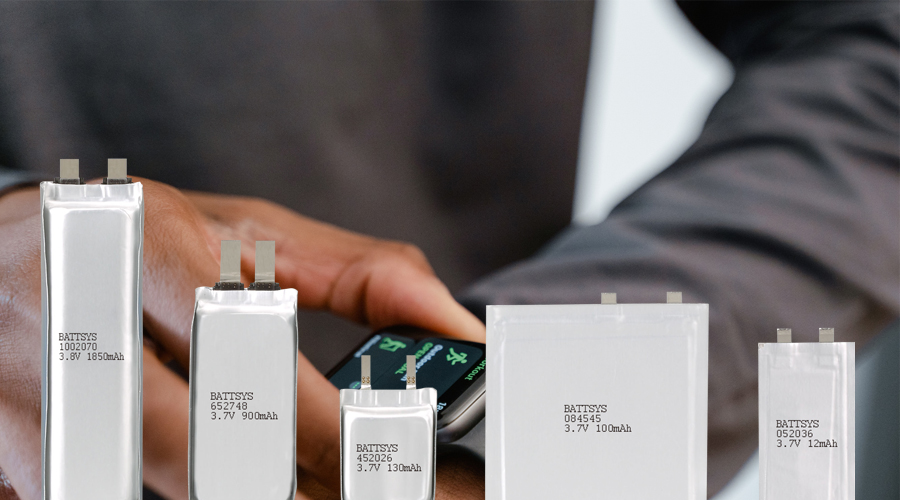

Soft pack lithium battery: It is a liquid lithium battery wrapped in a polymer shell. The structure type uses aluminum-plastic film packaging, and in the event of safety hazards, the soft pack battery will only have bulging cheeks and cracking at most.

Hard pack lithium batteries: There are two types of subdivision: cylindrical and square. Each packaging structure has its own advantages and disadvantages, mainly in response to different market demands. Ensuring consistency in hard pack lithium batteries is relatively difficult, with an increasing number of models and difficulty in achieving complete consistency in processing technology,

Suitable for customized production and manufacturing, not conducive to automated production of lithium batteries.

Characteristics of lithium battery soft pack

Widely used and now very popular in the 3C digital industry:

From the perspective of the appearance of the soft pack polymer lithium battery. The soft pack can have any shape, and assembling a soft pack pool for motor vehicles can increase the space of the vehicle. On the other hand, the assembly position of the soft pack battery is not affected by the structural type of the motor vehicle

Extremely thin and occupying a small space, it can make the battery thinner. The overall operational flexibility and compatibility of soft pack batteries are relatively high, which has great appeal for enterprises in terms of design concepts and other aspects;

High safety performance, the structure type of soft pack battery adopts aluminum-plastic film packaging. The biggest competitive advantage of aluminum film packaging is that it has a certain degree of softness. When the battery has safety performance problems, soft pack batteries usually have bulging cheeks and cracking, and the liquid inside leaks out, which will not cause the gas to be unable to be discharged and lead to explosion and fire. Soft pack polymer lithium batteries are relatively small in size and light in weight. On the other hand, they have a large capacity, low internal resistance, and flexible design concepts, which gradually show competitive advantages and dominant positions.

The internal resistance of small soft pack batteries is lower than that of lithium batteries. Currently, the minimum internal resistance of domestic soft pack battery cells can be below 32 square meters, greatly reducing the self consumption of lithium battery packs. The shape of flexible soft pack lithium batteries can be customized according to customer market needs to explore market cell models.

Is a soft pack or a hard pack better for lithium batteries?

The difference between lithium battery soft pack and hard pack mainly refers to the material of the outer shell of the lithium battery pack. If there is packaging on the outside, it is difficult to distinguish. It is important to see the battery body. Aluminum shell batteries weigh more than batteries of the same volume, but it is really difficult to distinguish between aluminum shell and soft pack. However, soft pack batteries are slightly softer than aluminum shell batteries and are extremely prone to deformation when broken by hand.

The difference between

lithium battery soft pack and hard pack can be said to be different, each with its own advantages and disadvantages. There are many soft pack lithium polymer batteries with high safety performance. Aluminum shell packaging such as 18650, the vast majority of lithium-ion batteries have a long lifespan. Soft packaging is the most primitive state of exhaust pipes, while hard packaging disperses hot spots, providing higher safety and performance.

Reminder: Lithium battery packs can be purchased through legitimate channels, and branded products are all tested and certified, ensuring better product quality and safety!