What is a battery pack?

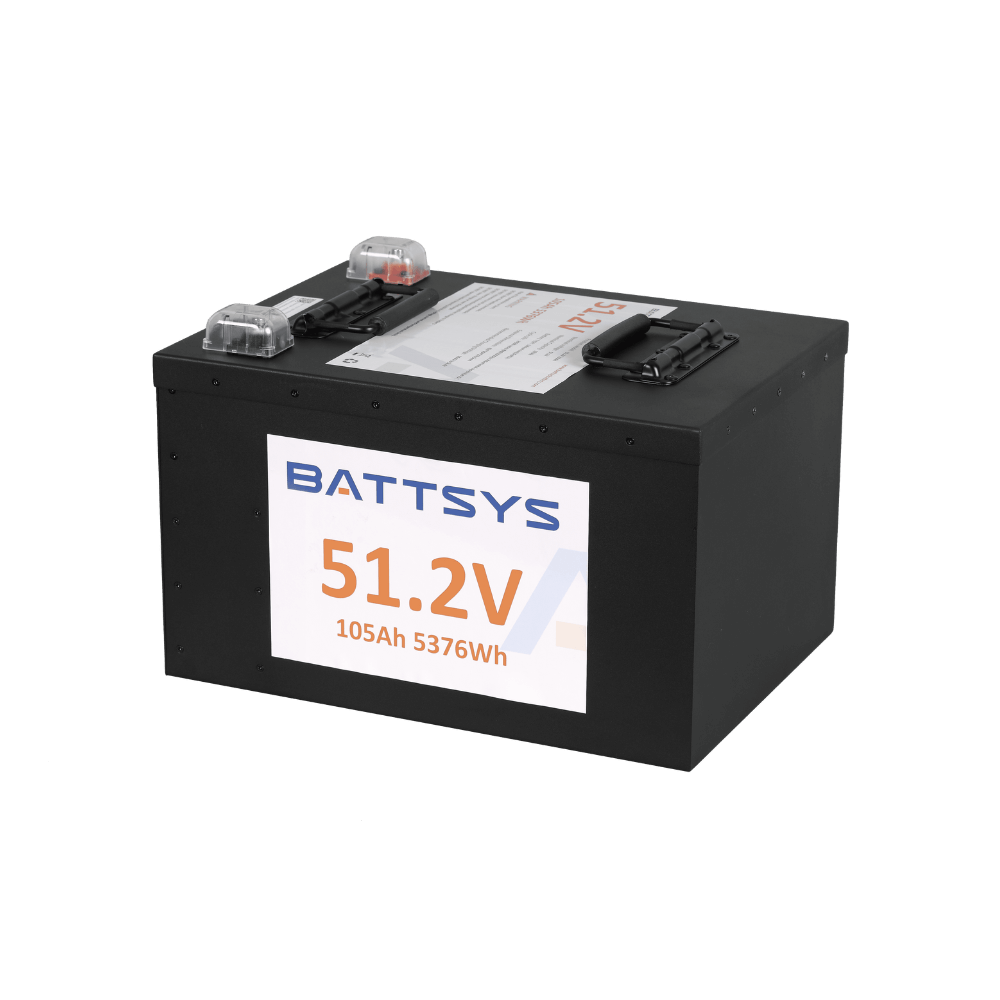

Battery PACK refers to the packaging/assembly of batteries

Battery PACK is widely used in nickel hydrogen batteries, lithium-ion batteries, and lead-acid batteries. PACK is also required for high voltage or high capacity use, but it is generally fixed in a relatively simple box and output lines can be led out, with few complex management systems added.

Traditional batteries generally do not require more consideration of PACK, such as disposable batteries with size 5. Lead acid batteries can be directly used in series and parallel without further consideration of battery PACK.

Nickel hydrogen and lead-acid batteries: PACK batteries of the same model can be directly connected in parallel and series, with consideration given to capacity consistency, basic consistency in charge, consistency in internal resistance, basic consistency in self consumption, and discharge rate. In fact, the self consumption of nickel hydrogen batteries is not much different, because their charging is about 150% of their capacity. Batteries with high actual capacity can release excess energy through hydrogen and oxygen evolution, achieving the final balance of the battery pack.

Generally, for nickel hydrogen battery packs, considering charging at 150% of the rated capacity, the excess energy basically undergoes hydrogen and oxygen evolution inside, and then combines internally to form water, which is ultimately consumed in the form of heat, generating a large amount of heat and causing temperature rise. Therefore, a temperature switch is added inside the battery to control the disconnection of high-temperature charging and protect the nickel hydrogen battery pack. On the contrary, the charging efficiency of lithium-ion batteries reaches over 90%, and the heat generation is mainly caused by physical resistance and polarization resistance. However, continuing to charge after being fully charged will only result in a continuous increase in battery voltage, ultimately leading to overcharging and even safety hazards.

Higher voltage demand from the user end:

The voltage of a single battery is 3.6V, and in actual use, higher voltage is required. Due to the accumulated habit of long-term use, different voltage habits such as 6V, 7.2V, 12V, 24V, 48V, 60V, 72V have appeared in many occasions. More importantly, under the same power output, higher voltage can effectively reduce the working current and heat generation, which is easier than increasing the voltage. The heating power of the physical resistor is P=I2R.

Requirement for larger capacity:

In more application scenarios, in order to improve the usage time of battery packs, a larger capacity requirement is needed, which means providing longer working time while meeting a certain working power, or vice versa, providing greater working power within a certain working time.

There are safety issues with

lithium batteries. From their own characteristics, lithium batteries have the following major problems

1. Overcharging safety hazards: After overcharging, there is a significant safety hazard of fire and explosion, theoretical analysis

2. Degradation of over discharge performance: After over discharge of lithium batteries, there is a possibility of lithium deposition, leading to a sharp decrease in capacity

3. Lithium batteries generally have charge discharge rate limitations and require protection against maximum continuous discharge current and short circuits.

4. Environmental limitations for lithium batteries: Charging and discharging are temperature limited and require temperature protection.

Customer's special requirements are met

1. Intelligent management requirements: Lithium batteries require knowledge of their actual SOC in many situations and require intelligent management.

2. Requirements for different application scenarios: Lithium battery packs have a large number of battery cells, which require consideration of specific requirements such as current carrying capacity, vibration protection, and waterproofing in practical applications

3. Meeting special customer needs: Customers can adapt to their specific housing, use battery cells with different magnifications, adapt to battery pack accessories, waterproof, temperature, heating or cooling, connectors, labeling, packaging and transportation conditions, and other special requirements based on their different usage needs;

4. Applicability requirements for safety regulations: Customers need to meet the applicability of corresponding safety standards in different countries or regions, requiring special design to achieve sales and usage in different regions.