Lithium-ion

batteries have been widely used in smartphones, electric vehicles, portable electronic

devices and energy storage systems due to their high power and energy density,

high voltage, long service life and low self-discharge rate.

Mileage, charging time and

safety of use are important indicators in various application scenarios.

However, the performance of lithium-ion batteries is significantly affected by

ambient temperature.

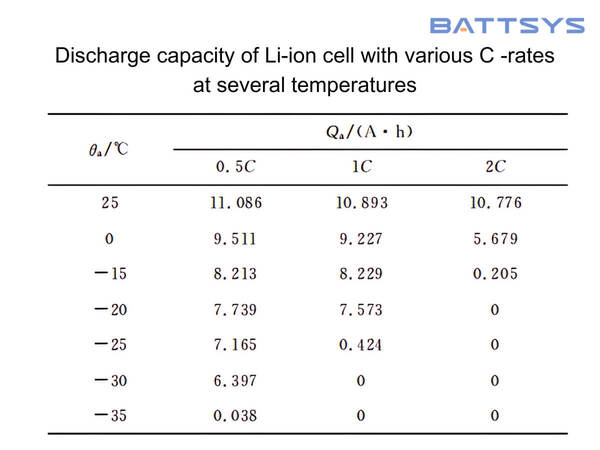

Particularly in low-temperature environments, the diffusion rate of lithium ions between the positive and negative electrodes slows down, the electrochemical reaction rate of electrode materials decreases, polarization intensifies, and the conductivity of the electrolyte decreases. These factors will lead to a significant decrease in the output power, energy density, and lifespan of lithium-ion batteries.

For

example: in the battery available capacity test, below 0℃, the

available capacity of the battery under different DOD decreases rapidly.

For

the performance of lithium batteries in low temperature environments, view the

article: Testing the performance of

lithium batteries in extreme cold environments

Currently, there are two main approaches to improve battery performance in low-temperature environments:

1. Research and development of electrolytes and electrode materials with better low-temperature characteristics.

2. Research on low-temperature heating strategies for batteries.

In the short term, developing battery materials that can adapt to low-temperature environments is challenging to guarantee. In comparison, researching low-temperature heating strategies from the perspective of battery thermal management systems is more feasible.

In this article, we will summarize the current preheating methods for lithium-ion batteries, comparing the advantages and disadvantages of different heating methods.

The low-temperature preheating systems for lithium batteries can be divided into two main categories: external heating and internal heating.

External heating can be further classified into two types: integrated heating and cooling, and direct heating using electric heaters.

Internal heating also has two main categories: self-heating and electrically stimulated heating.

1. External Heating

External heating involves using an external heat source to warm up the battery. It features a simple structure, mature experience, and wide application. However, external heating methods suffer from drawbacks such as slow heating speed, low energy utilization efficiency, and uneven temperature distribution.

1.1 Integrated Heating and Cooling Design

The thermal management system of lithium-ion batteries can not only be used to cool down the batteries but also to heat them up. Depending on the working medium of the thermal management system, it can be classified into three main categories: air, liquid, and phase change materials.

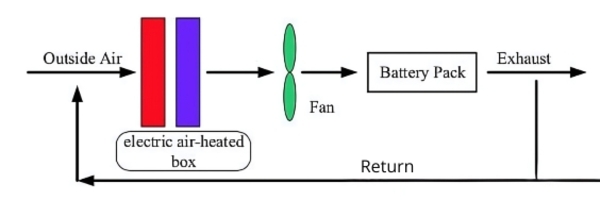

1.1.1 Air Preheating:

Air-based thermal management systems are characterized by their simple structure and relatively low cost. In this system, external air is first heated by the heating system and then circulated into the battery pack by a fan to provide heating to the batteries.

Typically, air preheating methods can achieve heating rates of 0.5-3°C/min. However, this approach often faces challenges related to noise and efficiency, which can be difficult to address.

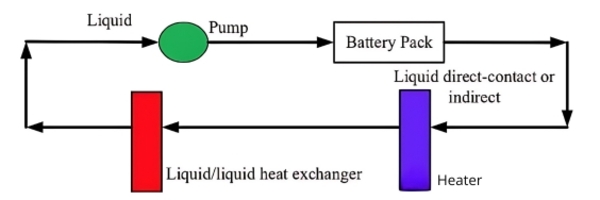

1.1.2 Liquid Preheating:

Compared to air, liquids have higher thermal conductivity and heat capacity, thus offering higher heat transfer efficiency.

Based on whether the battery is in direct contact with the conductive liquid during heating, liquid preheating can be divided into two main categories:

1)Non-contact heating;2) Immersion heating.

1.1.3 Phase Change Material (PCM) Preheating

Air or liquid preheating methods add complexity and cost to the battery system. Phase change materials offer a simpler preheating approach by utilizing the heat released or absorbed during phase change to heat or cool the battery. However, PCM has low thermal conductivity, which is not conducive to rapid heat transfer.

Preheating.jpg)

1.2 Electric Heater Preheating:

Electric heater preheating can be divided into the following categories:

1)Peltier effect heater; 2)Heating elements; 3)Heating sleeves; 4)Heating films.

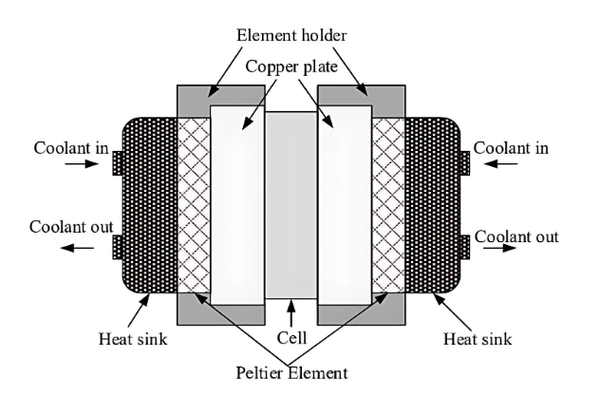

1.2.1 Peltier Effect Heater:

The Peltier effect heater utilizes the Peltier effect in semiconductors to create a hot and cold surface on its two sides. By controlling the direction of the electric current, the position of the hot and cold surfaces can be adjusted to achieve battery cooling or heating. The temperature is controlled by the amplitude of the electric current, allowing for heating rates of 0.6-1°C/min. Preheating the battery consumes approximately 2.5% of the battery's energy.

1.2.2 Heating Element Preheating

Heating elements are typically located at the top or bottom of the battery and are made of positive temperature coefficient (PTC) materials. They directly transfer the generated heat to the battery. As the temperature rises, the resistance increases to achieve temperature self-regulation.

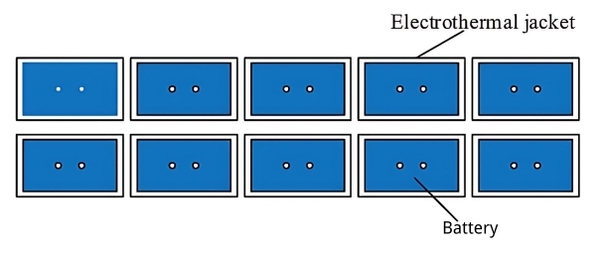

1.2.3 Heating Sleeve:

This method involves making a battery protection sleeve with a thermistor, which is wrapped around the battery. The temperature changes are monitored by the Battery Management System (BMS) to control preheating. It can preheat the battery to the operating temperature within 10 minutes and maintain temperature uniformity.

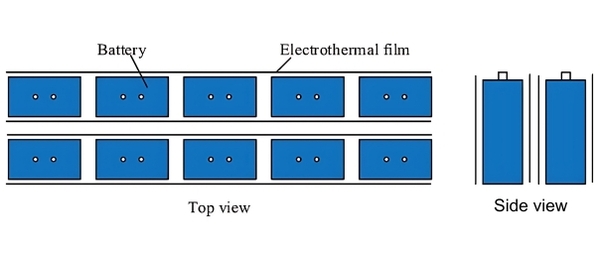

1.2.4 Heating Film

Heating film is made by laminating metal foil and insulation material, with a thickness of 1-2mm. It is applied to the surface of the battery, occupying minimal space. Compared to positive temperature coefficient (PTC) heating elements, heating film can achieve higher heating rates with lower energy consumption.

2. Internal Heating:

In lithium-ion battery preheating, internal heating is faster and more efficient than external heating. However, its control mechanism is complex, and there are safety concerns. It mainly includes self-heating and current-induced heating.

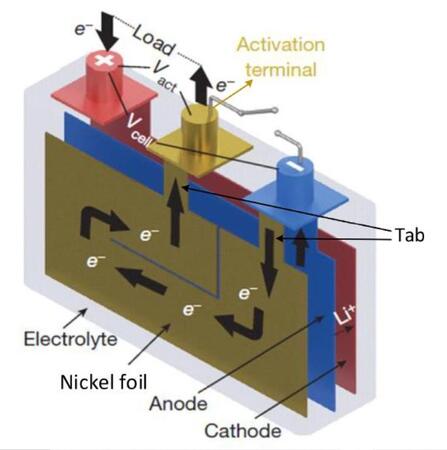

2.1 Self-Heating Method:

This method involves inserting a nickel foil into the interior of the battery and then leading out the electrode externally. The battery's heating is controlled by an external circuit. With this approach, the heating rate can reach up to 60°C/min when heating the battery from -30°C to 0°C.

2.2 External Current-Induced Heating Method:

This method includes several approaches such as DC current preheating, AC current preheating, and pulse preheating.

2.2.1 Direct Current Preheating Method:

This method involves applying a direct current discharge current to the battery to heat it up using the heat generated during the discharge process. The heating rate of a 18650 battery can reach 4.29°C/min. However, high current discharges can cause polarization of the battery, accelerating capacity degradation, and potentially reducing the battery's cycle life to only about 81 cycles.

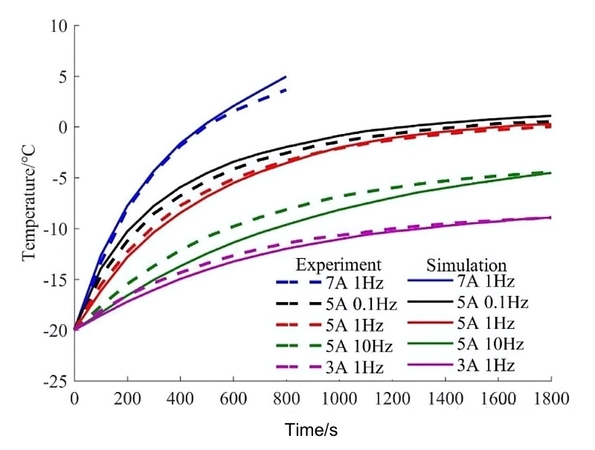

2.2.2 Alternating Current Preheating Method:

AC heating involves applying an alternating current to the battery to generate heat, utilizing the internal impedance of lithium-ion batteries to internally heat the battery. The cyclical charge and discharge processes can quickly heat up the battery. Compared to the DC heating method, AC heating has a faster heating rate and higher efficiency. Among them, sinusoidal AC current is the most widely used.

2.2.3 Pulse Current Preheating Method:

The pulse current preheating method involves using discontinuous high-current discharges to generate heat through the internal ohmic impedance of lithium-ion batteries, achieving preheating of the batteries.

In conclusion:

Currently, air preheating and liquid preheating methods, due to their simple structures, have been applied in electric vehicles. Air preheating, mainly utilized in early electric vehicles with lower energy density, is preferred for its lower thermal conductivity and space requirements. Liquid preheating, known for its high efficiency, is becoming increasingly widespread. Recently, internal heating methods have attracted attention for their exceptionally high efficiency, but they still face numerous challenges and have not yet been applied in electric vehicles.

The above summarizes the current lithium battery preheating methods and compares the advantages and disadvantages of different heating methods.

E-Mail: inquiry@fentbattery.com

Tel: 0086 20 3901-1403

Address: No.3, Dongli Road, Xili, Dongyong Town, Nansha District, Guangzhou City, China

Copyright@ China lithium ion battery manufacturers & suppliers & producers | Lithium Battery Factory & Company-BATTSYS Sitemap