This article will introduce in detail the four major characteristics of large cylindrical steel shell lithium batteries(4680 battery): large volume and high capacity, electrodeless lug design, high energy density, and dry electrode technology.

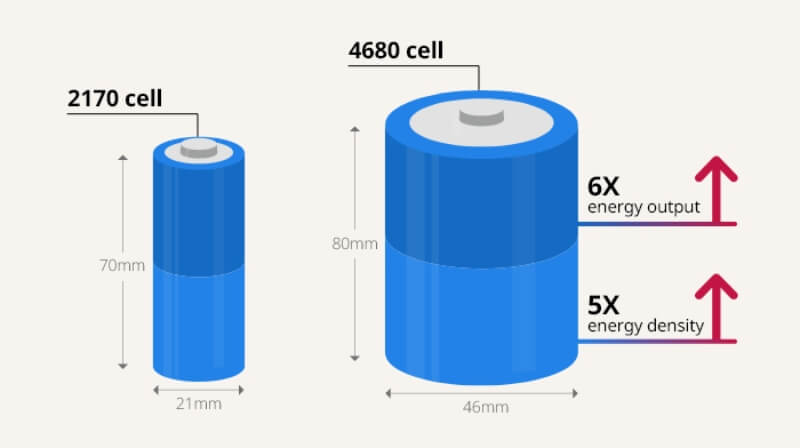

A large volume means the ability to encapsulate more active materials (such as positive and negative electrode materials), thereby achieving a significant increase in the capacity of individual batteries. The capacity of 46800 batteries can be about five times that of 21700 batteries.

Continuously increasing the size will raise

safety concerns and risks to the battery's cycle life. In terms of diameter,

the vehicle's range begins to decrease starting from 46mm, and the marginal

benefits of cost reduction diminish. Therefore, considering both the

performance and cost of battery packs, a 46mm diameter is the preferred option

in terms of performance and economy at the current technological level.

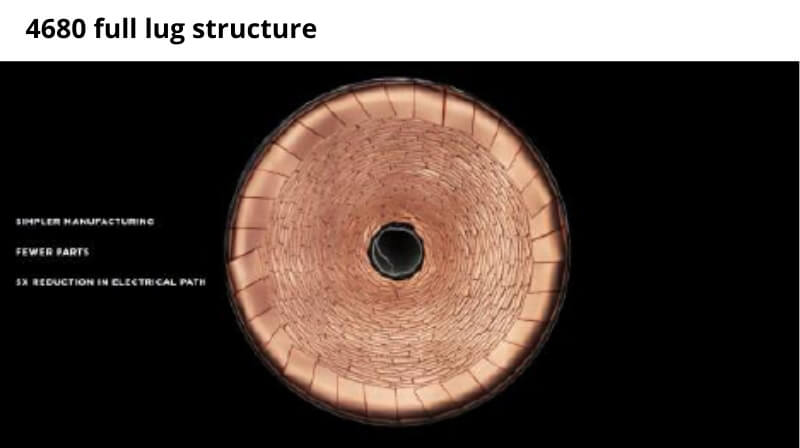

Traditional cylindrical batteries have tabs

on the top and bottom for connecting to external circuits for power

transmission. The large cylindrical battery adopts an all-lug design.

Design advantages of non-pole ear (all-pole

ear)

Monopole ear structure: electrons flow in

the current collector through the entire spanwise length of the wound pole

piece;

Full lug design: the path of electrons in

the current collector is only the axial length;

Comparison: the circulation path is

shortened, the internal resistance of the battery is reduced, the conduction

area is increased, and the heat dissipation area is increased;

Advantages: Improved rate performance, fast

charging and larger current discharge. Theoretically, the charging speed can be

increased by about 6 times and the internal resistance can be reduced to

one-fifth of the original.

Utilizing high-nickel cathodes and silicon

anodes increases energy density, with high-nickel cathodes and silicon anodes

being employed in the 4680 battery.

Regarding cathode materials, increasing the nickel content not only enhances the battery's energy density but also reduces the relatively expensive cobalt content, thereby lowering the cost of cathode materials.

Concerning anode materials, silicon offers

a higher gravimetric capacity than existing graphite systems. An anode with

high gravimetric capacity can enhance the battery's energy density.

Traditional electrode coating employs a wet

process, where electrode powder is mixed with solvents to form a slurry, which

is then evenly coated onto the current collector foil. The solvent is later

dried and recovered.

In the dry electrode process, electrode

powder is directly mixed with the binder PTFE and coated onto the current

collector via roll pressing. This method eliminates the energy-intensive drying

step, thus reducing the production cost of battery cells.

Simplified Process: Eliminates the drying step after coating the slurry of electrode powder mixed with binder solvent onto the current collector foil in the traditional wet process.

Cost Reduction: Saves on raw material costs for solvents and equipment costs for solvent use, evaporation, and recovery.

Improved Electrode Performance: The binder exists in a fibrous form, allowing for closer contact between the electrode's active materials and conductive agent particles. This results in improved conductivity, higher capacity, and faster charge-discharge rates.

Compatible with Lithium Replenishment Process for Negative Electrodes: Dry electrode technology eliminates the need for organic solvents, allowing direct use of lithium powder during negative electrode replenishment, thereby optimizing the issue of low initial efficiency.

The emergence of 4680 redefines cylindrical batteries, which will drive comprehensive breakthroughs in the fields of positive electrode materials, negative electrode materials, packaging technology and structural parts, and drive technological innovation in the whole industrial chain.

E-Mail: inquiry@fentbattery.com

Tel: 0086 20 3901-1403

Address: No.3, Dongli Road, Xili, Dongyong Town, Nansha District, Guangzhou City, China

Copyright@ China lithium ion battery manufacturers & suppliers & producers | Lithium Battery Factory & Company-BATTSYS Sitemap