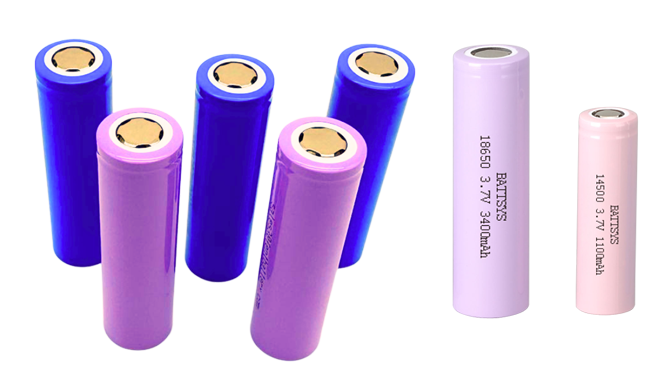

Common abnormalities in the winding of

18650 lithium battery cells.

1. Poor distance between the center of the ear and the pole

2. CPP gets stuck in the diaphragm or exceeds the diaphragm too much

3. The adhesive tape after wrapping the film at the extreme ear position exceeds the diaphragm for too long

4. The negative pole of the adhesive tape is not wrapped around the positive pole

5. Poor appearance (wrinkling of the foil, protrusions, damage to the polarizer, etc.)

6. Leakage of polarizer (incoming polarizer has wavy edges, polarizer is curved)

7. Polar flipping

8. Too many short-circuit cells

The impact of poor winding of 18650 lithium battery cells on subsequent processes.

1. The width of the battery cell is too wide

The bare cells in the packaging process will not be able to be placed inside the cell packaging box.

2. Poor distance between the center of the ear and the pole

Cells that undergo the hard sealing process will not be able to fit into the ear slots of the fixture, and the cells will not be able to be soldered onto the circuit board at the back.

3. CPP gets stuck or exceeds the diaphragm too much

Excessive immersion: After packaging, the CPP of the battery cell will not be able to be exposed, which can easily lead to a single pole ear short circuit

Exceeding too much: After packaging, the CPP of the battery cell is exposed too much, which can easily cause a single pole ear short circuit and affect the soldering of the circuit board for the subsequent battery cells

4. The adhesive tape of the extreme ear position exceeds the diaphragm for too long

When sealing the top of the battery cell, the adhesive paper falls onto the sealing area, affecting the packaging effect of the battery cell.

5. The negative electrode of the battery cell is not wrapped around the positive electrode

Lithium absorption will occur on the negative electrode, causing a short circuit between the positive and negative electrodes.