Working principle of high-temperature lithium battery.

High temperature lithium batteries are rechargeable batteries that rely heavily on lithium ions to move between positive and negative. During the charging and discharging process, Li intercalation and deintercalation occur between two electrodes: in a rechargeable battery, Li is debited from the positive electrode and inserted into the negative electrode through the electrolyte, with the negative electrode in a lithium rich state; In the discharge process, the opposite is true. Lithium based materials are representative of ancient high-performance batteries. The working principle of lithium-ion batteries is the charging and discharging principle. When a high-temperature lithium battery is discharged, electrons act simultaneously with Li in the same direction, but through different pathways. Electrons pass through an external circuit and move from negative to positive; Lithium ion Li from negative; Jump in; Electrolyte leakage; Swimming; Reached positive and combined with running for a long time. During the charging and discharging process of high-temperature lithium batteries, lithium ions move from positive to negative and then back to positive. If we compare lithium-ion batteries to rocking chairs, the two ends of the rocking chair are the two ends of the battery, and lithium-ion is like a good athlete running back and forth between the two ends of the rocking chair. So experts gave batteries a terrible name, rocking chair batteries. The structure of high-temperature lithium batteries consists of five parts: positive, negative, electrolyte, barrier, shell, and electrical leads. The structure of high-temperature lithium batteries can be divided into two categories: surrounding type and deposition type. Liquid high-temperature lithium batteries have a surrounding structure, while polymer high-temperature lithium batteries also have a surrounding structure. Negative materials: active materials, conductive agents, solvents, adhesives, substrates. In high-temperature lithium batteries, the positive data market has a high capacity and added value, accounting for about 30% of the cost of high-temperature lithium batteries. The gross profit margin is at a low level of 15% and at a high level of over 70%. At present, the data has been widely used in high-temperature lithium batteries, including lithium cobalt oxide, lithium manganese oxide, lithium nickel nickel manganese oxide, lithium cobalt nickel manganese oxide, and lithium iron phosphate. Negative data: active substances (graphite, MCMB, CMS), binders, solvents, and substrates. The proportion of negative charge data in the cost of lithium batteries is relatively low, and it mainly includes carbon negative data and non carbon negative data. Barrier: As a device for isolating electricity, barrier is placed between two to avoid direct contact between the two active materials, which can cause internal short circuits in high-temperature lithium batteries. The barrier still needs to allow charged ions to form a pathway through it. Important high-temperature lithium battery barrier material products include single-layer P P, P

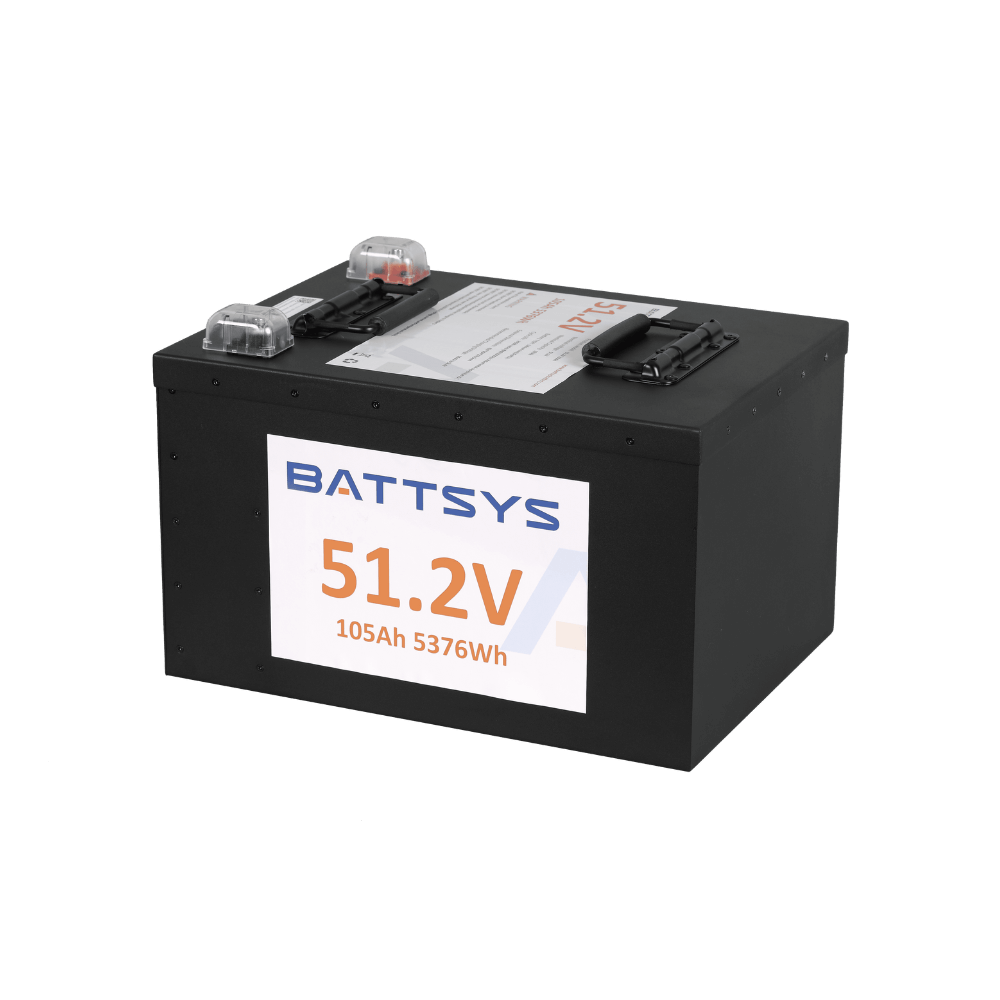

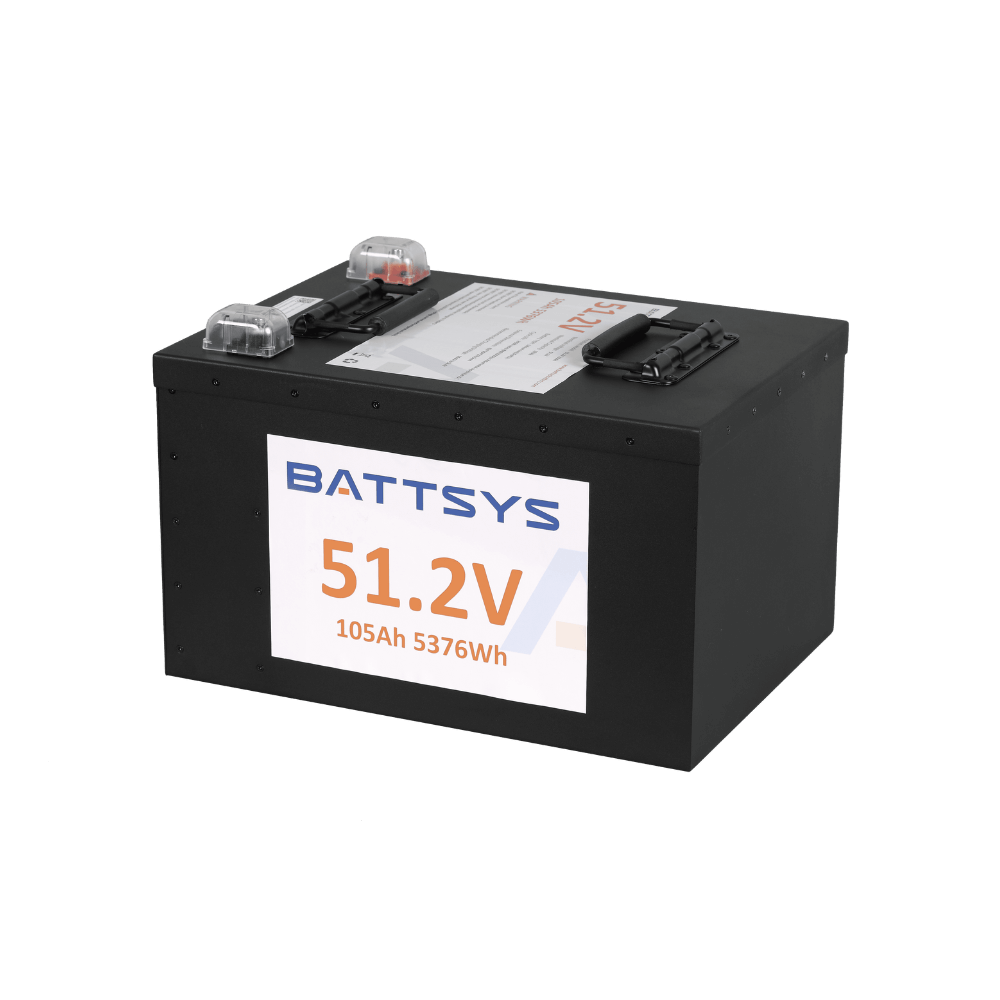

5-year warranty . 3500+ cycles. Charging can last for 8 months.

5-year warranty . 3500+ cycles. Charging can last for 8 months.

5-year warranty . 3500+ cycles. Charging can last for 8 months.

5-year warranty . 3500+ cycles. Charging can last for 8 months.

E-Mail: inquiry@fentbattery.com

Tel: 0086 20 3901-1403

Address: No.3, Dongli Road, Xili, Dongyong Town, Nansha District, Guangzhou City, China

Copyright@ China lithium ion battery manufacturers & suppliers & producers | Lithium Battery Factory & Company-BATTSYS Sitemap