What kind of battery is used for solar street lights? Is it safe?

Shaping is different.

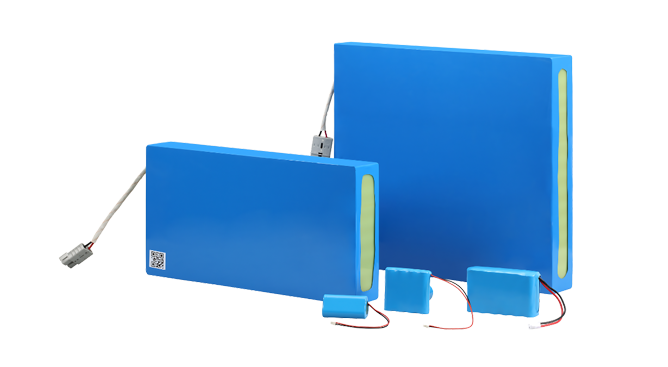

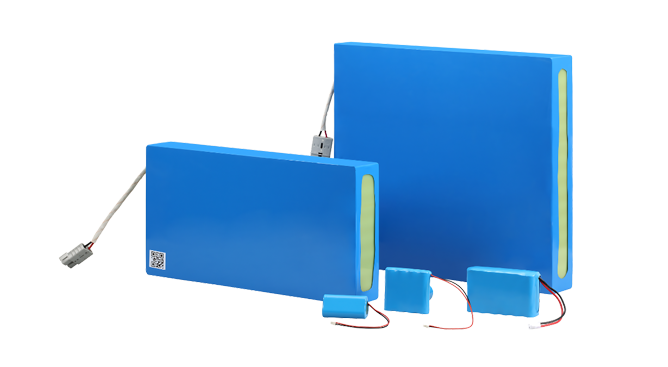

Due to the differences in the two electrolytes, their shapes also vary greatly, mainly because of their different electrolytes. The electrolyte of polymer lithium batteries can be solid or colloidal, which greatly improves the flexibility of battery shape design. It can become thinner and theoretically can achieve a thickness of less than 0.05mm. It can also achieve any area and any shape to better meet the needs of products, providing solar street light developers with high design flexibility and adaptability for batteries of any shape and capacity, and maximizing their product performance.

The electrolyte of liquid

lithium batteries uses electrolytes and requires a sturdy casing as secondary packaging to accommodate them, which limits their size, shape, and increases the weight of the lithium battery.

The raw materials are different.

The battery structure mainly includes a positive electrode, a negative electrode, an electrolyte, and an electrolyte, and at least one or more of them are made of polymer materials in polymer lithium batteries. Polymers here refer to objects with high molecular weight, typically possessing high strength, toughness, and elasticity.

However, for the currently produced polymer lithium ions, polymer materials are mainly used for positive electrodes or electrolytes. The positive electrode material adopts inorganic compounds of general lithium-ion batteries or conductive polymers, while the negative electrode usually uses lithium metal or lithium carbon interlayer compounds.

Electrolytes are made from solid or colloidal polymer electrolytes. This electrolyte is similar to plastic film. It cannot conduct electrons, but can allow ion exchange (rechargeable atoms or groups of atoms) to replace traditional porous membranes immersed in electrolytes.

The main difference in materials for liquid lithium batteries is that their electrolytes are made of liquid or colloidal electrolytes.

The safety performance is different.

In terms of safety, polymer lithium batteries also show great advantages.

Polymer lithium batteries are mostly soft packaged batteries, and the outer shell is generally made of aluminum plastic film. This material has good ductility, flexibility, and mechanical strength, and also exhibits excellent barrier and heat sealing properties.

Moreover, the electrolyte inside is solid or colloidal, with no excess electrolyte, making it relatively stable and less likely to cause danger due to excessive battery charging, needle puncture, collision or other damage, as well as overuse. Of course, things are not * *. If you are in extremely harsh environments, such as excessive instantaneous current, short circuits are not impossible.

But compared to liquid lithium batteries, it is safer. Liquid lithium batteries are prone to leakage, have a sturdy casing, poor heat dissipation, and a high possibility of explosion.