Battsys 36 volt lithium marine battery High utilization structural design; eight/volume reduced by 30%~50%.80% charge in 30 minutes, 20% charge in 5 minutes.DurableLifespan up to 10 years, 3500+ cycles; zero maintenance, 5-year warranty.

Marine lithium batteries are battery systems specifically designed for use in ships, using lithium-ion technology in order to provide high energy density batteries.

It is characterized by high safety, high energy density, intelligent operation and long life, which can meet the demand of marine power system. Marine lithium battery realizes real-time monitoring of battery data status, automatic equalization, automatic protection, intelligent charge/discharge management through battery management system (BMS) to ensure safety and prolong life. .

Battsys is the best 36 volt lithium marine battery Manufacturer with Premium Quality, Battsys 36 volt lithium marine battery High utilization structural design; eight/volume reduced by 30%~50%.80% charge in 30 minutes, 20% charge in 5 minutes.DurableLifespan up to 10 years, 3500+ cycles; zero maintenance, 5-year warranty.

5-year warranty . 3500+ cycles. Charging can last for 8 months.

Learn More

5-year warranty . 3500+ cycles. Charging can last for 8 months.

Learn More

5-year warranty . 3500+ cycles. Charging can last for 8 months.

Learn More36V Marine lithium batteries have a wide range of application scenarios, floor cleaner machines, aerial work platforms,including but not limited to RVs, outdoor activities, electric propellers, lawn mower accessories, electric vehicle batteries, etc.

2. long cycle life, lithium batteries can be recycled, suitable for long-term ocean voyages.

3. Energy saving and environmental protection, lithium battery is a kind of green power supply, no pollution.

4. good maintainability, lithium batteries are easy to maintain, suitable for the poor maintenance conditions of the ship.

2. safety risks, lithium batteries have a certain risk of fire and explosion, a threat to the ship's safety. 3. limited life span, lithium batteries are easy to maintain, suitable for ships with poor maintenance conditions.

3. limited life, lithium battery power supply time is long, but there is a limit, need to consider replacing. 4. poor low-temperature performance.

4. Poor performance in low temperature, lithium battery capacity and power will be reduced in very low temperature, not conducive to the ship polar navigation.

5. power supply stability, lithium battery output fluctuations, need to be mixed with other power supply to ensure power supply stability.

The lifespan of 36V lithium batteries is usually between 3-5 years. However, this data is only for reference, as everyone's usage habits and environment are different.

A 12V charger can't charge a 36V lithium battery because of voltage mismatch, current and power mismatch: besides voltage, current and power are also important parameters of the charger. If the current and power of the charger don't match with the battery, it may lead to unstable charging process and even damage the charger and the battery. In this case, using a 12V charger to charge a 36V lithium battery may lead to problems in the charging process or even damage the battery due to the mismatch of current and power.

Marine lithium batteries are worth the investment. Marine lithium batteries are used in a wide range of application scenarios, including but not limited to RVs, outdoor activities, electric propulsion, lawnmower accessories, and electric car batteries. These applications cover not only personal use, but also professional equipment and commercial use, showing the diversity and usefulness of marine lithium batteries.

Lithium batteries are ideally suited for marine use due to their unique advantages and technological maturity, such as their high safety, long life and good temperature adaptability, and are playing an increasingly important role in marine power systems

Lithium battery voltage 36V, the standard charging voltage of the charger is 42V; charging current 1-2A.

Its high cost puts greater pressure on the overall cost of the ship; at the same time, lithium batteries have fire and explosion and other safety hazards, posing a threat to the safety of the ship. In addition, the power supply time of lithium batteries is long but limited, and needs to be replaced regularly; in the extremely low temperature environment, its performance will be greatly reduced, which is not conducive to the navigation of the ship in extreme conditions such as the polar region.

The life of marine lithium batteries is related to different use environment and maintenance methods, and the general service life is 3-5 years. Some can even reach 8-10 years.

A 36-volt lithium battery is about 600 dollars, this price is relatively cheap, the quality of the battery can be bought better. Now most of the forty-eight volt battery, basically have to sell most of them are Tianneng and Chaowei lead-acid batteries, are a piece of all twelve volts, the price is about eighty dollars.

The application of lithium batteries in ships shows a number of significant advantages. First of all, it has high energy density characteristics, which makes lithium batteries able to provide a large amount of energy in a limited space, perfectly adapting to the ship's compact layout. Secondly, Li-ion battery has a long cycle life, which is especially critical for long-term ocean voyage. Furthermore, lithium battery is an environmentally friendly power source with no pollution emission, which helps ships realize green navigation. Finally, lithium batteries are relatively easy to maintain, even under the poor maintenance conditions of the ship can maintain a good working condition.

In recent years, with the increasing number of electric ship demonstration projects, lithium batteries for electric ships have also experienced the process from scratch.GGII research data shows that the domestic shipment scale of lithium batteries for ships in 2023 was 0.32GWh, with a compound growth rate of 40% from 2019-2022.

With the large-scale application of lithium batteries in the field of power and energy storage, the rapid decline in their cost will further reduce the initial cost of electric ships and promote the development of electric ships to speed up.

2. The integrated development of ship power exchange and energy storage has become a trend. The power exchange mode can increase the ship's range and reduce the charging time in harbor, which is an important means to solve the range anxiety. In addition, “plug-and-play” type containerized battery can utilize peak and valley electricity price difference for energy storage, which can enhance the economy.

Battery-powered ships are currently one of the most novel ship types in the world, and their electrification features can provide a foundation for the development of the next generation of smart ships. Its design and construction are not a simple replacement of the power system, and require innovation in design and construction concepts. It is a huge challenge for both the design and construction departments. The configuration of ship systems and functions, requirements for equipment operation and crew skills, the impact of the operating environment on the ship, and the prevention and handling of accidents and risks are more complex than conventional power ships. All classification societies and maritime departments are in the initial stages of research, and the relevant research and design systems are not yet complete.

1. Industry status quo

From a global perspective, the application of battery-powered ships is in the exploration and demonstration period, with insufficient operating experience. As of the end of May 2019, the number of electric ships in the world was 155, including 75 operating ships and 80 ships planned to be built. The application of large-capacity battery-powered ships between 1000KWh and 4000KWh has been realized.

2. Current status of port supporting facilities

Port supporting facilities, especially charging facilities, are one of the factors limiting the development of electric ships.

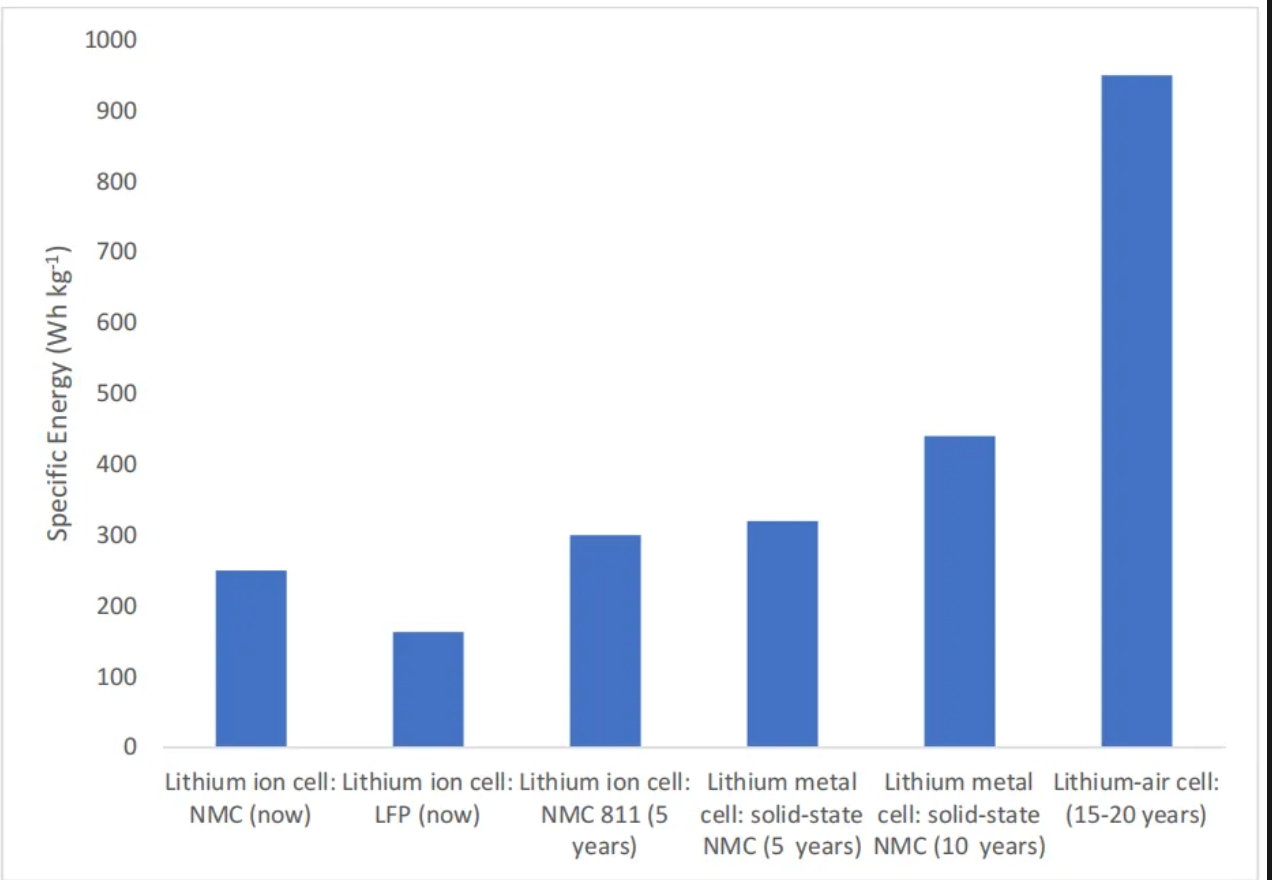

There is always the question of which type of battery to use. Lithium-ion batteries are a continuously developing battery type, mainly due to the selection of negative electrode materials. The most popular anode material for marine and automotive applications is nickel manganese cobalt (NMC), which provides high safety and has a very good specific energy (see figure below). However, NMC has its own thermal stability problems and is highly dependent on cobalt, a scarce and expensive material. In addition, there are moral hazard issues in the supply chain.

Figure: Specific energy of battery chemical materials expected to be used in the marine field in the next 5-20 years

What is certain is that the widespread application of solid-state lithium batteries is expected to be the next major advancement in the field of energy storage in the next 3 to 5 years. In the next 10 years, there will be a second generation of new solid-state batteries that can provide closer to their theoretical performance. Lithium battery. The solid electrolyte effectively prevents the risk of dendrite growth that could cause battery short circuits and helps the lithium metal cathode function. Solid-state lithium batteries have a specific energy up to 75% higher than the current best lithium-ion batteries. And the impact on safety may be even greater: with the risk of fire and even cooling requirements all but eliminated, the specific energy of marine battery packs could triple within 10 years, with a similar increase in achievable ranges.

Ship lithium battery shipments are expected to exceed 50GWh in 2035

The next 10 years will also see a series of progressive increases in anode materials, including high-nickel and lithium-rich, both of which have higher voltage and capacity than today's anode materials. There is a certain compromise when it comes to negative electrode stability, but this is fully resolved by the inherent safety of solid electrolytes. The development trend of anode materials is to reduce or exclude cobalt while increasing specific energy and voltage. At present, one anode material that is unlikely to be used in ship applications in the short term is lithium sulfur. Although its energy density is twice that of today's lithium-ion batteries, it does not improve the volumetric energy density of lithium NMCs. It also has life cycle issues that cannot be completely solved, but it is increasingly considered an ideal battery material for aerospace applications, such as drones (where weight is a crucial factor). Sodium has been touted as a potential replacement for lithium because it is abundant (in seawater) and has many crossovers with lithium ions in manufacturing, electrode and electrolyte technology, but sodium ions are actually larger, heavier ions, Has a low electrochemical potential. In addition to the reduction in specific energy, larger sodium ions intercalate/extract from the electrode thereby shortening the cycle life of the battery. Other alternatives tend to have comparable performance to lead-acid batteries (less than 50Wh/kg), including flow batteries (already commercialized for grid energy storage) and aluminum batteries (currently developed in the laboratory). From a practical standpoint, these batteries will largely not be used in future ships before 2050. Finally, in the next 15 to 20 years, lithium-air batteries (or other metal-air batteries) may become available. Although the theoretical specific energy of lithium-air batteries is 3500 Wh/kg, the maximum specific energy value in practical applications is 950 Wh/kg. Metal-air batteries may also face the same problems as fuel cells, namely slow discharge rates, and may also require support from higher-power cell types. However, this battery type is still in the laboratory research stage, with little evidence that a breakthrough is imminent. If the specific energy of lithium-air batteries reaches four times that of today's lithium-ion batteries, it is expected to become an important contributor to future transportation energy storage.

Our excellent sales and technical team help your business find the best Rol rate

E-Mail: inquiry@fentbattery.com

Address: No.3, Dongli Road, Xili, Dongyong Town, Nansha District, Guangzhou City, China

0086 20 3901-1403Copyright:Guangzhou Battsys Co.ltd