Industrial lithium batteries are used in photovoltaic and new energy sources, electric power and switchgear, petroleum and petrochemical, railroad equipment, medical equipment, marine and offshore, personal mobility devices, floor cleaners, industrial utility vehicles, forklifts and logistic trucks etc.

Industrial lithium batteries are chemical batteries for industrial use. The types of industrial lithium batteries include 18650 lithium batteries, lithium iron phosphate batteries, power/storage batteries and lithium polymer batteries, which are selected according to the parameter requirements of the power-using equipment in the actual application.

Industrial lithium batteries are used in photovoltaic and new energy, electric power and switchgear, petroleum and petrochemical, railroad equipment, medical equipment, ships and marine, personal mobility devices, floor cleaners, industrial utility vehicles, forklifts and logistics vehicles.

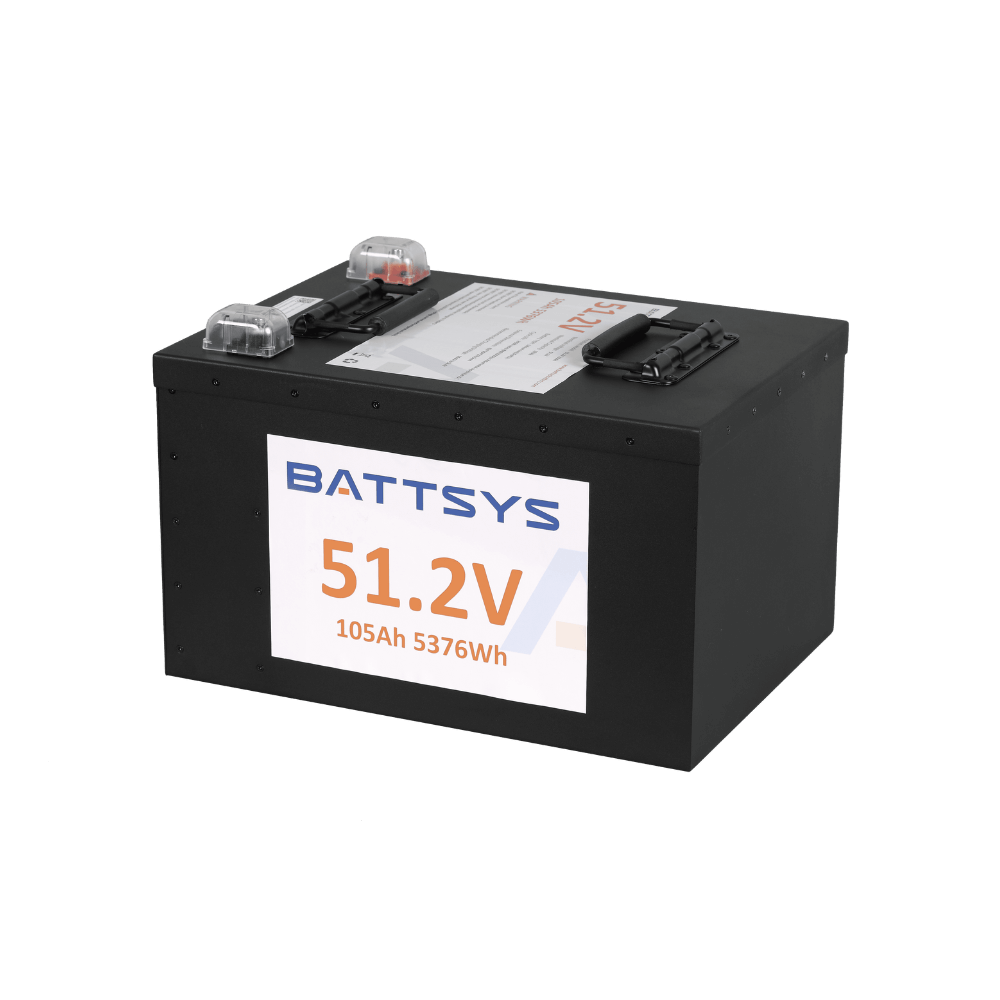

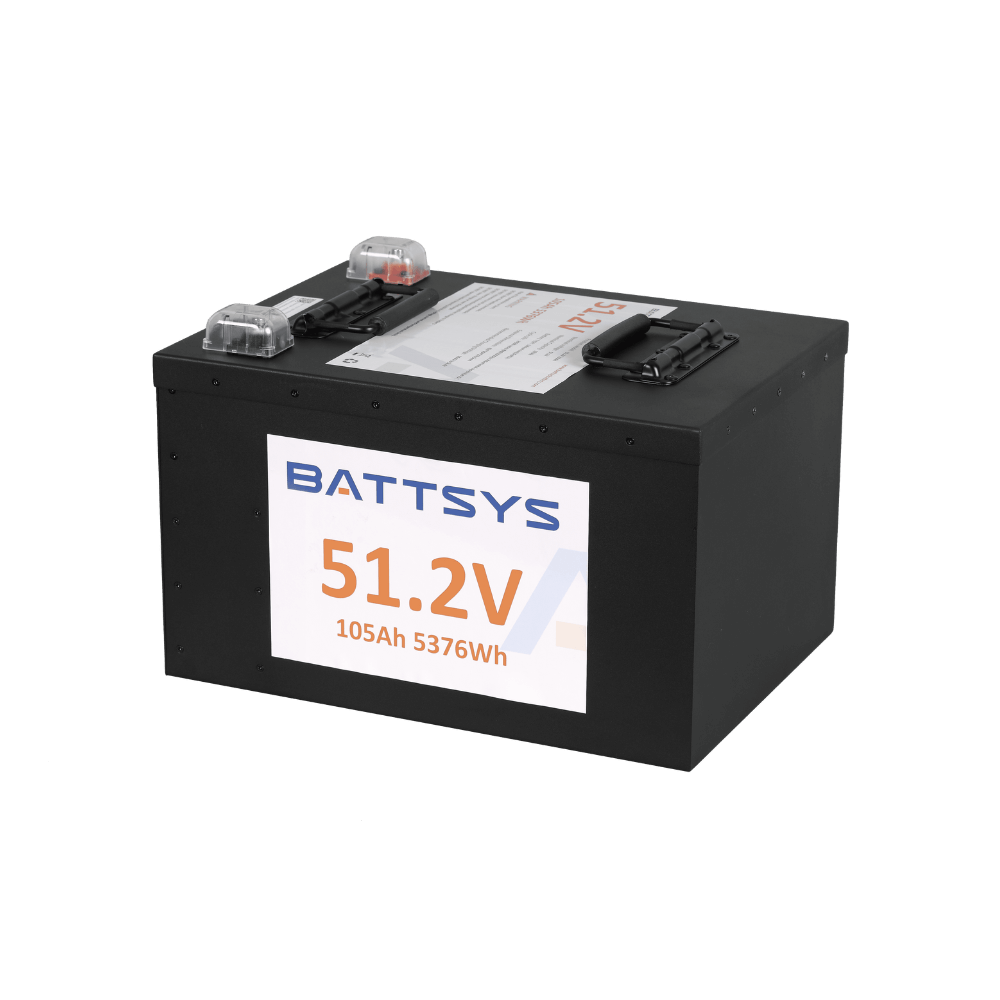

Battsys is the best Li-ion Battery Manufacturer with Premium Quality, Fast Global Shipping, 3-7 Days Lead Time, Accept OEM & ODM, and Small orders available.Battsys Forklift lithium batteries are 80% charged in 10 minutes for zero maintenance and longer running time.

5-year warranty . 3500+ cycles. Charging can last for 8 months.

Learn More

5-year warranty . 3500+ cycles. Charging can last for 8 months.

Learn More

5-year warranty . 3500+ cycles. Charging can last for 8 months.

Learn MoreIndustrial lithium batteries are used in photovoltaic and new energy sources, electric power and switchgear, petroleum and petrochemical, railroad equipment, medical equipment, marine and offshore, personal mobility devices, floor cleaners, industrial utility vehicles, forklifts and logistic trucks etc.

There are three main types of industrial lithium battery power supply cells on the market today: 18650 cells, polymer cells, and lithium iron phosphate cells.

18650 cell

The positive material of 18650 cell has high working voltage (average working voltage is 3.7V), smooth charging and discharging voltage, small size, high specific energy, good cycling performance, high conductivity, simple production process and easy to manufacture.

Advantages: mature technology, wide range of applications, compact size.

Disadvantages: cycle life of about 300 times, low safety performance, poor resistance to overcharging, not suitable for high rate charging and discharging, environmental pollution after disposal.

Polymer battery cell

Advantages: volume diversity, very wide range of use, not easy to explode, high safety coefficient.

Disadvantages: higher price, pollution of the environment after disposal, weak performance of high-current charging and discharging. Polymer batteries are not divided into domestic or imported or dismantled like 18650 batteries, it is divided into three qualities, respectively, A product, B product, C product.

Lithium iron phosphate battery cell

Advantages: safe, reliable, long life, 2000 cycle life, high current charging and discharging, small internal resistance, less heating, safety, environmental protection and non-toxic.

Disadvantages: expensive price, battery pack life is generally about 500 times, and low temperature performance is not good.

1.the service life is not the same

Industrial lithium batteries have a fairly long service life, than ordinary lithium batteries need to extend the service life of a lot. Industrial lithium batteries use a patented lithium protection technology, the battery capacity can reach 15Ah, than ordinary lithium battery life up to three times. In addition, according to the test, industrial lithium batteries do not need any maintenance and its management, the battery itself can complete the reuse, and even to achieve 5 years. And general lithium batteries if there are abnormalities need to charge maintenance or replacement of batteries must be in decades. And most of the users in the use of a week or so will be prone to discharge problems, there is no way to use.

2.low productivity, high cost

In industrial applications lithium battery production efficiency is relatively low, the productivity is not high is undoubtedly, but this also aims to reduce costs. Generally speaking, industrial lithium battery cost per battery will be relatively high, if it is mass production, then the cost per battery will be higher than the average battery. So industrial lithium batteries are less efficient than normal lithium batteries and will cost more to produce. Moreover, there are times when the production cost per section of industrial lithium batteries is lower than the average cost per section of ordinary lithium batteries.

3.industrial lithium batteries have a wide range of applications, wide conditions of application

In industrial applications, lithium batteries can be used in vehicles, electronics, communications equipment and other fields. And general lithium batteries can only be used in the military field, such as rockets and missiles. In addition, industrial lithium batteries can also be directly used in other areas, such as industrial robots and machine equipment and other fields. Therefore, industrial lithium batteries have a wider range of applications.

Our excellent sales and technical team help your business find the best Rol rate

E-Mail: inquiry@fentbattery.com

Address: No.3, Dongli Road, Xili, Dongyong Town, Nansha District, Guangzhou City, China

0086 20 3901-1403Copyright:Guangzhou Battsys Co.ltd